NAMPA, Idaho — Today on “Keepin' It Local,” I'm going to take you to a 3D printing farm, one of only a handful in the world. Slant 3D in Nampa is on the leading edge of a new industry helping businesses in need of plastic parts in a whole new way. Here's how.

"So these are the parts and products that started it all."

This is Gabe Bentz the President of Slant 3D.

He started his entrepreneurial adventure making these little robots, Little Bots, he calls them. When sales took off he needed an efficient and affordable way to crank them out. That's when Slant 3D was born.

"We needed to produce our own product and then it got large enough that it could be a resource to other people creating products," said Bentz.

“So people can make large quantities of parts without that high initial cost of molds and tooling."

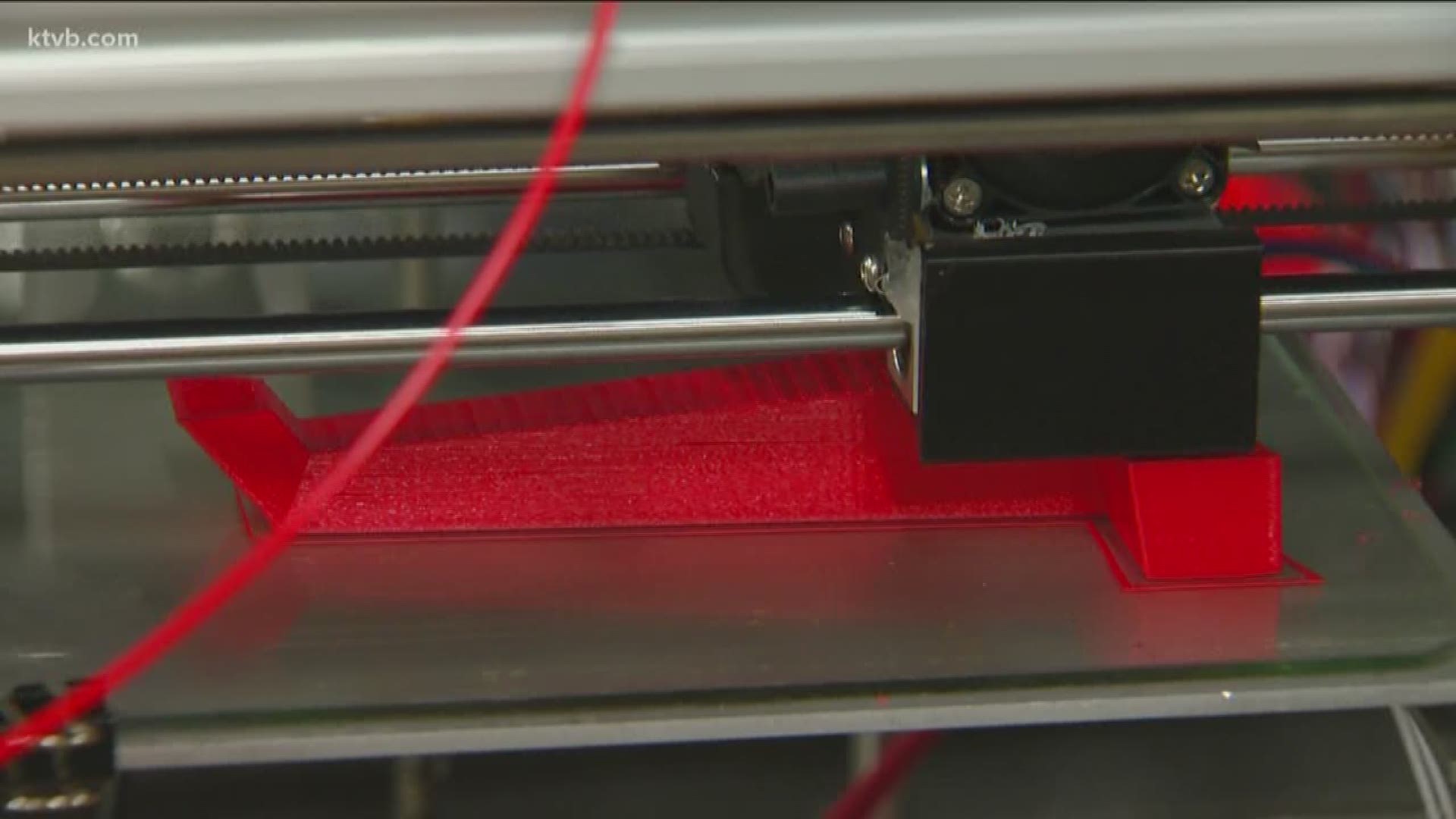

With large banks of 3D printers, the farm as Gabe calls it, works around the clock.

"If you're starting a new product of some kind you don't want to have to build all the infrastructure yourself when you get started.

We save 100 percent of the cost of tooling. Molds can be five to $10,000 to get your first part. Here with 3D printing you're able to get a thousand parts for a thousand dollars. That is not possible with traditional manufacturing."

Slant 3D has hit on a need and the variety of orders they now get runs the gamut.

"So right now we're working on a number of parts for RC cars, a company in California is building. Some of these other machines are working on simple parts like pencil holders."

"One of the most recent ones this echo dot holder for Nickelodeon we did during the Christmas season for them."

But what's their most interesting order so far?

"One of the best orders we've ever done is actually in prosthetics. We worked with a company called Limbforge where they make prosthetic hands for kids in Africa. They were just simple hands to be marginally functional and those are the really neat kind of projects that come through that we get to work with."

"It's fun to see what other folks are creating and it's fun to be working with something that the answers aren't all there yet."

Right now, Slant 3D is able to produce about 10,000 parts per week, but that will be increasing significantly soon. This is definitely an Idaho company on the move.

Next week I'm going to show you how Slant 3D leveraged the help of the Small Business Development Center to get his company off to a great start. It's a largely free resource for business that you or someone you know might be able to utilize too.